Building the Longteng Innovation System

Leading Longteng's comprehensive improvement of business philosophy through technological innovation strategy

Talents are the core force of enterprise development and the source of creating enterprise value. Longteng Special Steel focuses on talent cultivation and team building, creating a high-quality, high-level, and highly skilled elite team, laying a solid talent foundation for the sustainable development of the enterprise。

7large

Research Chief Engineer Team

1000+

Research team

800+

Professional and technical talents

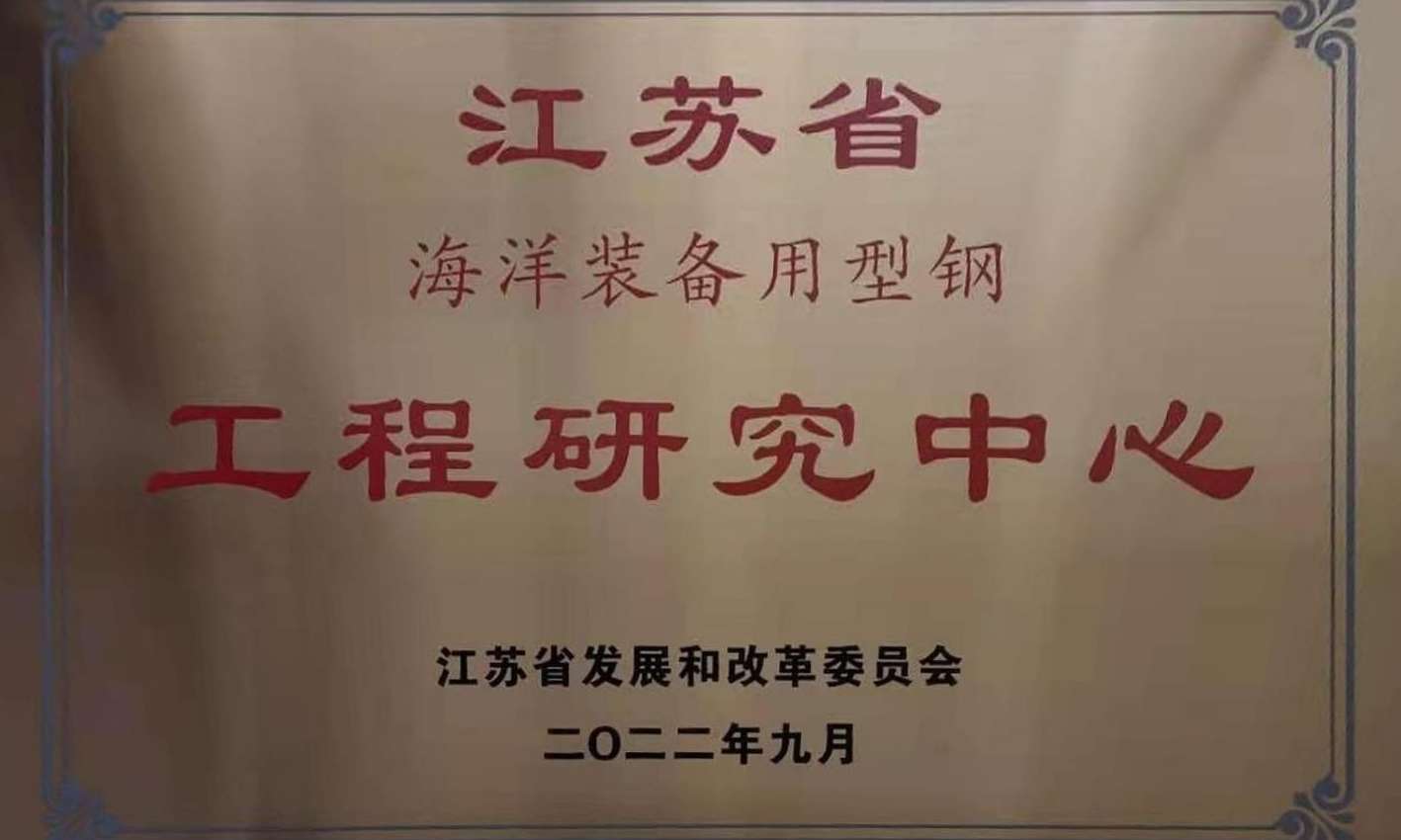

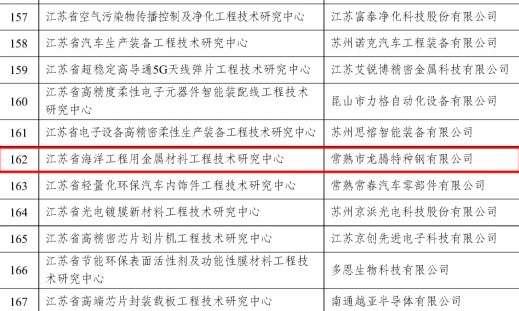

Construction of three major professional innovation platforms

- State-leveled enterprise

Technical Center

- Jiangsu Province Marine Equipment Steel Project

research center

- Metal Materials Engineering for Marine Engineering in Jiangsu Province

Technical Research Center

Maintain deep cooperation with domestic and foreign higher education institutions

Longteng and Beijing University of Science and Technology jointly founded the "Innovation and Development Research Institute", and has been cooperating with many well-known domestic research institutes such as Beijing University of Science and Technology, Northeastern University, Jiangsu University of Science and Technology, Nanjing University of Engineering, Changshu Institute of Technology, and Beijing Iron and Steel Design and Research Institute for a long time. The cumulative investment in research and development funds is nearly 3 billion yuan, greatly enhancing the company's technological innovation momentum。

Mastering cutting-edge industry technologies

8term

National standard revision

20term

Industry standard revision

420term

Industry patents

Ace technology

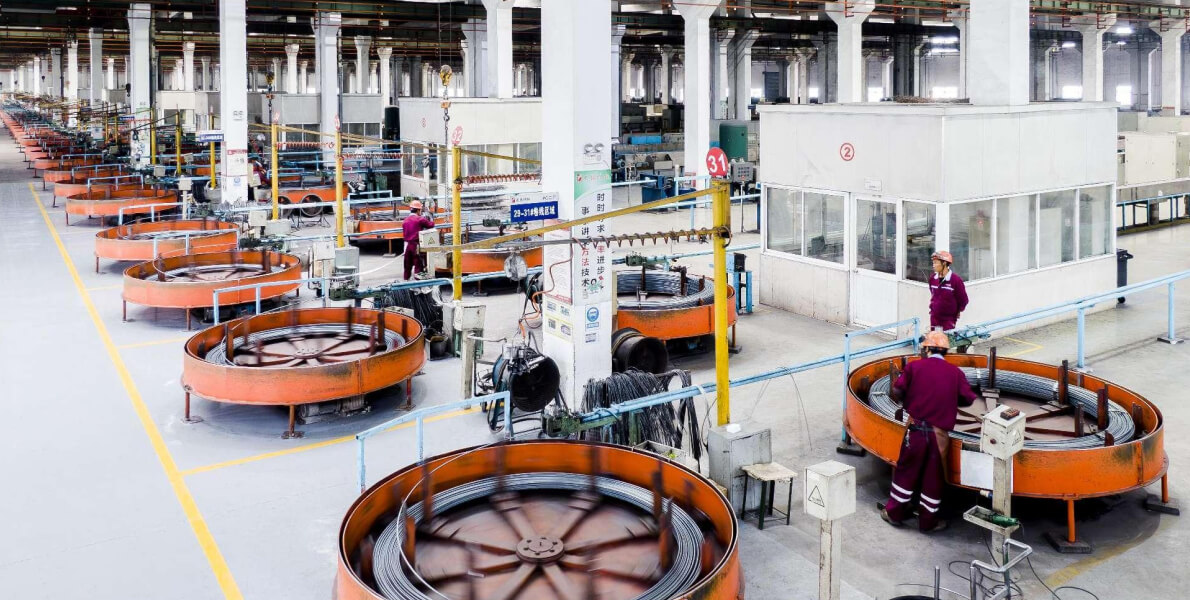

Adhere to the path of differentiated development, adhere to the development strategy of small products and large markets, and actively build a new development pattern

- Ball flat steel

The first domestically developed "dual straightening+strong straightening" micro deformation bending control technology。

The product market share has been over 50% of the national market share for 13 consecutive years。

Steel provider for the world's first largest bidirectional ice breaking polar scientific research vessel, "Xuelong 2"。

- Wear resistant ball

The international first semi self grinding "spatiotemporal dynamic ball adding method" and ball mill "spatiotemporal delayed ball adding method"。

The domestically pioneering automated hot forging steel ball production process combining die forging and free forging has won the international leading evaluation of scientific and technological achievements from the China Metallurgical and Mining Enterprise Association for its innovative achievements。

"Manufacturing Single Champion",The overall scale ranks first in China and second in the world。

- PC steel rod

Independently innovating 30MnSiL steel grades that are not prone to brittle fracture, solving the key technology of steel rod brittle fracture bottleneck, with a brittle fracture rate below 0.1 ‰ and a national market share of 85%。

"Manufacturing Single Champion",Being in a leading position in the industry, it is known as the "crown of Chinese PC steel bars".

Scientific research achievements

Longteng has obtained multiple honors and numerous patent achievements in the field of scientific research, and is constantly improving and developing。

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

Advanced Manufacturing

The company has always adhered to the principle of "extending the industrial chain, enhancing the value chain, and connecting the supply chain", seeking differentiated improvements in segmented markets, and developing "specialized, refined, unique, and new" products in a coupled manner. It has now become a comprehensive steel enterprise that integrates traditional industries and deep processing

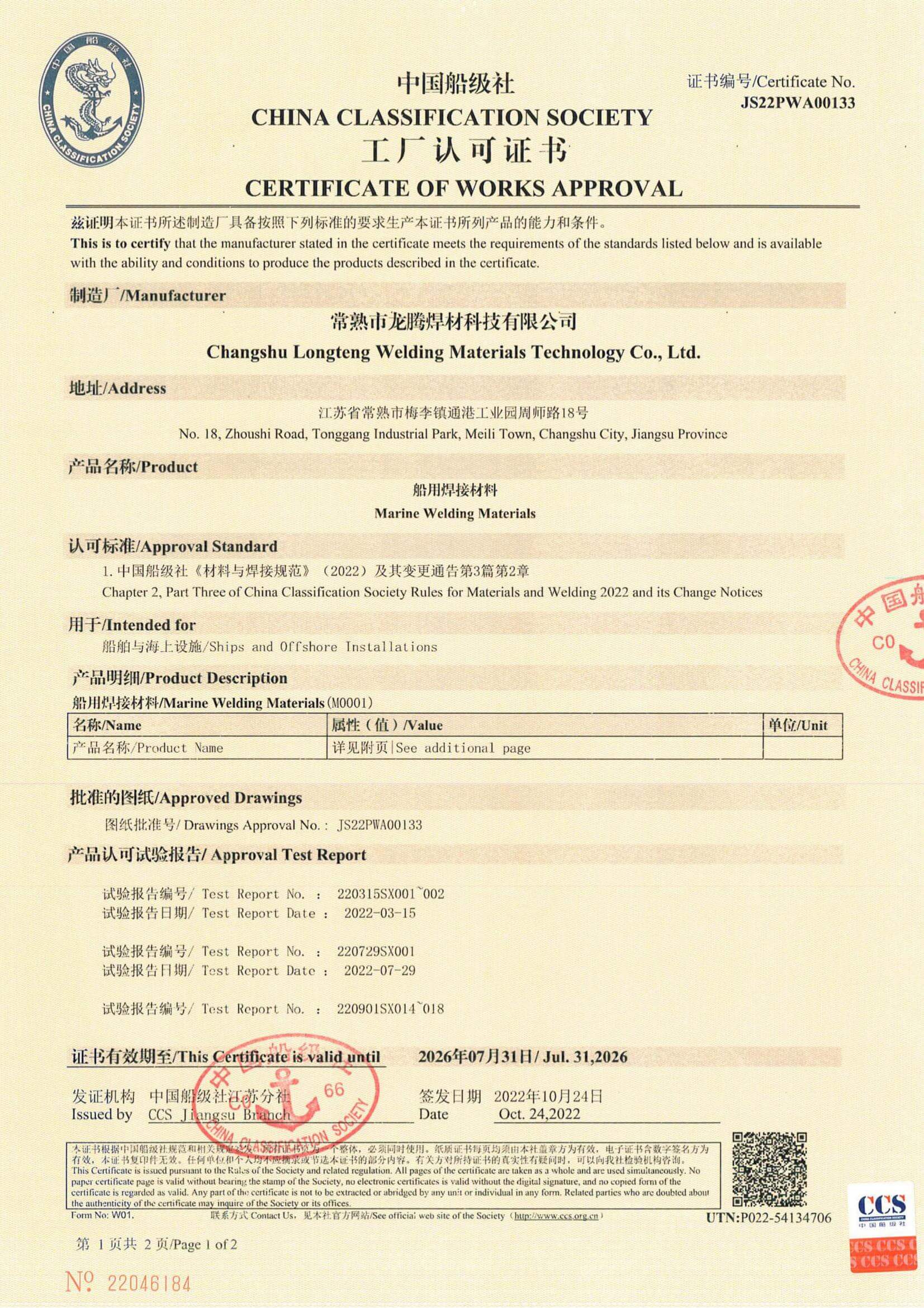

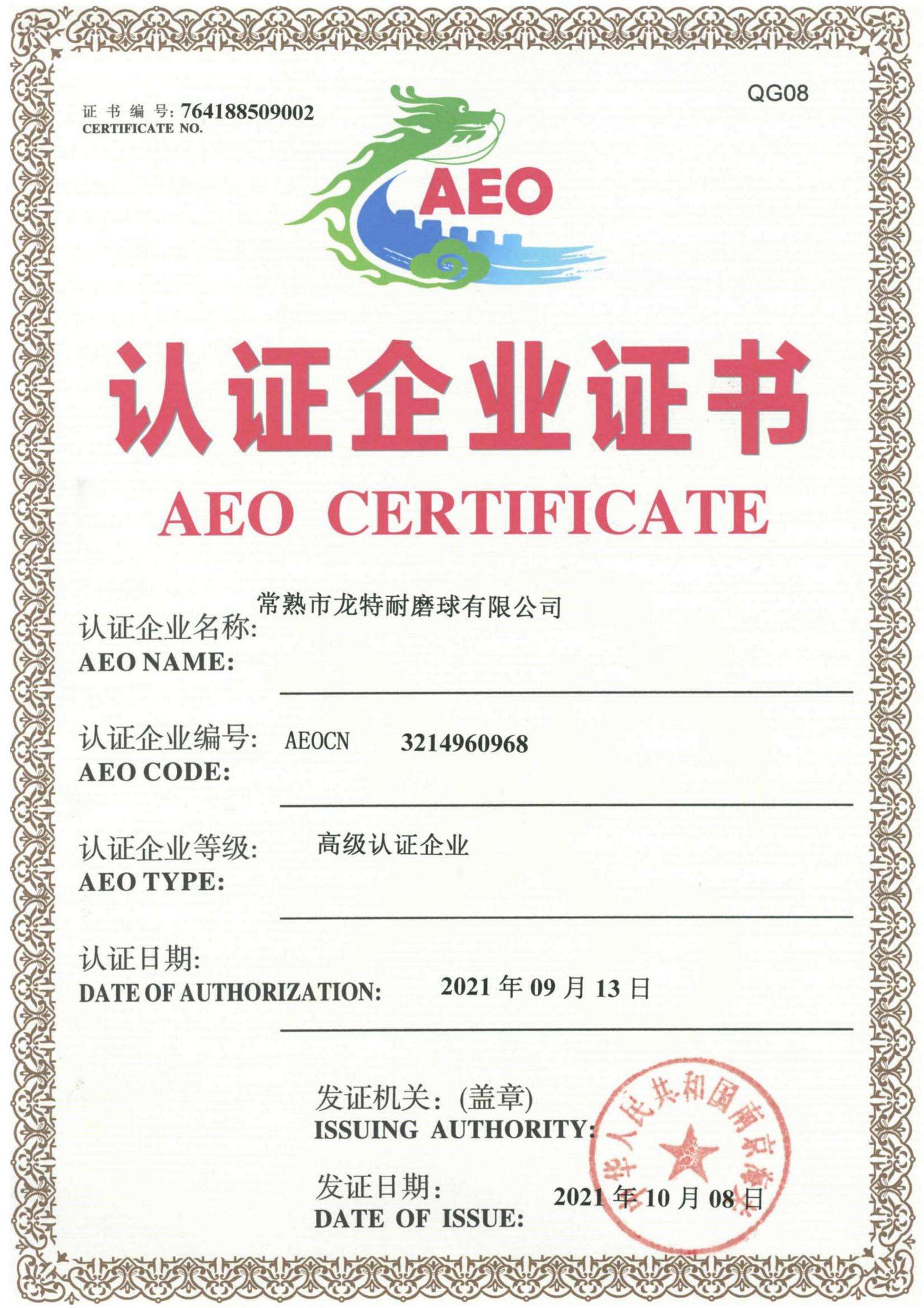

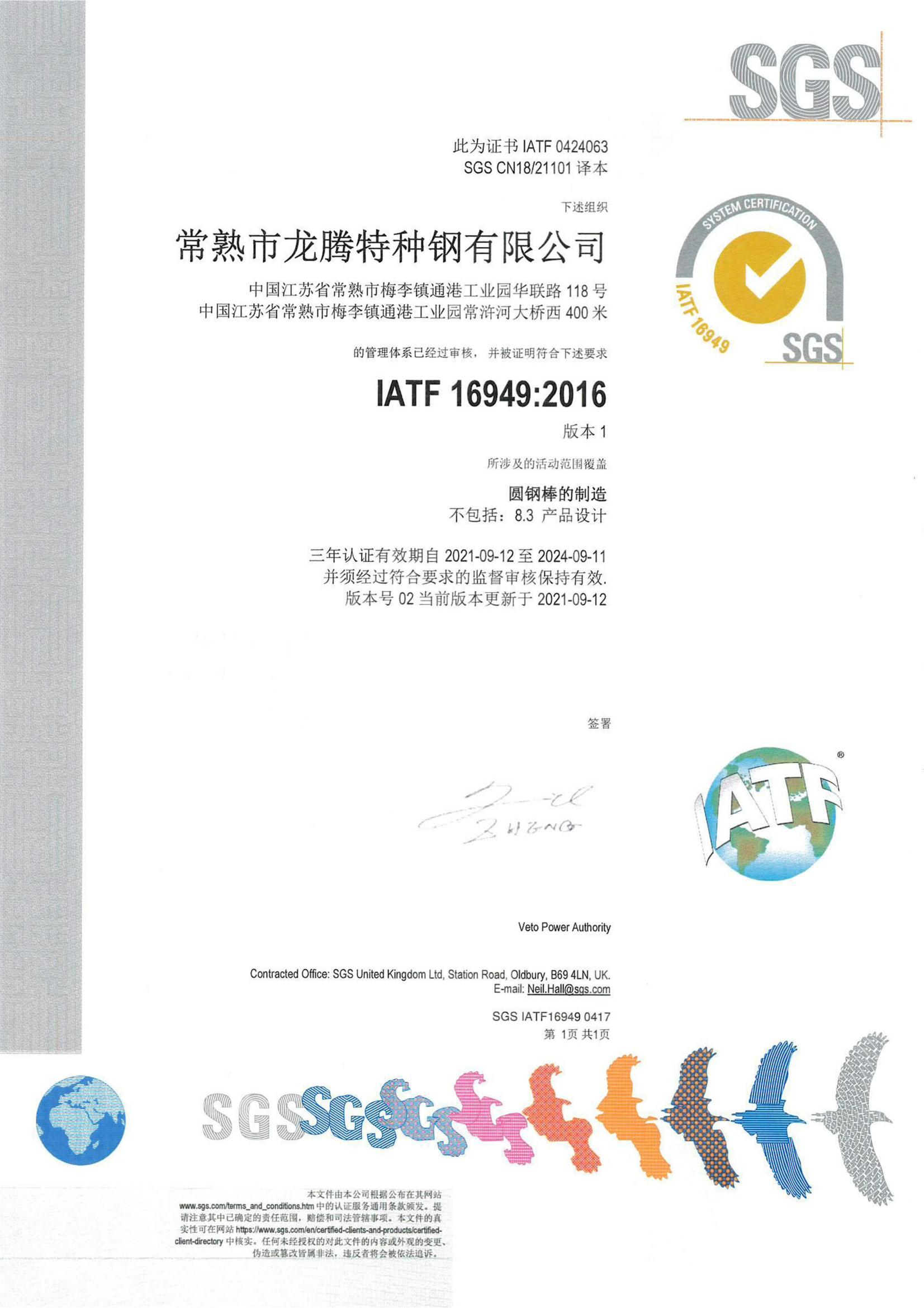

Quality builds reputation, innovation drives development

Passed management system certifications such as ISO9001, ISO14001, ISO45001, ISO50001, GB/T 23001, IATF16949, as well as factory and product certifications from the top ten global classification societies in China, Italy, the United States, the United Kingdom, France, Japan, South Korea, Russia, Germany, and Norway

Quality System Certificate

-

China Classification Society Factory Accreditation Certificate

China Classification Society Factory Accreditation Certificate -

AEOCN 3214960968

AEOCN 3214960968 -

Measurement assurance confirmation certificate

Measurement assurance confirmation certificate -

ATF16949:2016 Management System Certification

ATF16949:2016 Management System Certification

Testing Center

The Testing and Analysis Center is responsible for the inspection and laboratory work of each branch, as well as various inspection and analysis work. Having the ability to inspect and analyze various performance indicators of raw materials, steel billets, and steel, possessing necessary testing and analysis capabilities in low and high magnification inspection, inclusion and gas analysis, chemical composition analysis, mechanical performance testing, and other aspects. Being able to quickly and accurately provide various testing and analysis results, serving various factories。

X-ray fluorescence analyzer

ARL Switzerland Import Direct Reading

Hydrogen oxygen nitrogen gas analyzer

Scanning electron microscope

HCS Infrared carbon and sulfur analyzer

Fully automatic tensile testing machine

Rockwell hardness tester

Fully automatic impact testing machine

Three station forging and other testing equipment

X-ray fluorescence spectrometer

HORIBA Oxygen Nitrogen Hydrogen Gas Analyzer

Micro computer screen display hydraulic universal testing machine

Hardness testing machine

Zeiss type scanning electron microscope

ARL direct reading spectrometer

Element analyzer

Metallurgical microscope

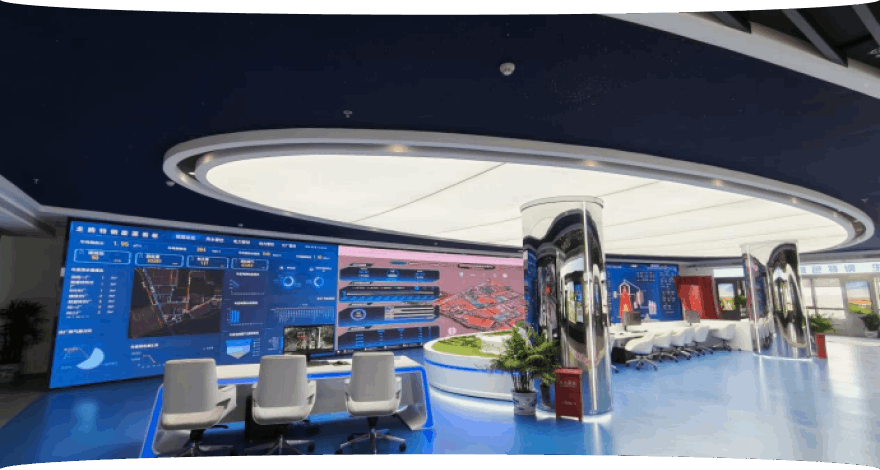

Digitalization empowers quality management

The company has carried out the construction of a quality management big data (digital platform) to achieve explicit and visual quality formation process

Email

Email