Green For steel

Longteng people deeply understand the essence of sustainable development, always putting environmental protection and safety production first in enterprise development, actively exploring innovation, and taking the path of extended development, green development, and harmonious development. Longteng Special Steel conscientiously implements the scientific development concept, adheres to the coordinated development of economic construction and environmental protection, relies on scientific and technological progress and scientific management, does a good job in environmental protection governance, implements clean production, creates an ecological enterprise, vigorously improves the environmental quality of the enterprise and surrounding areas, guarantees the health of employees, achieves synchronous improvement of enterprise economic benefits, environmental benefits, and social benefits, and promotes sustainable development of the enterprise

Compliance with laws and regulations, improvement of the environment, elimination of pollution, energy conservation and consumption reduction

Longteng Special Steel has invested 5 billion yuan in environmental protection, energy conservation, and ecology, enabling Longteng to achieve high-quality development of the enterprise through green construction。

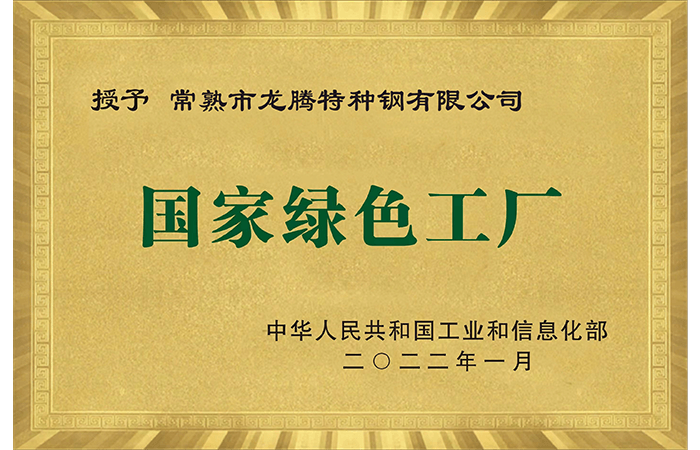

National level green factory

National level green factory

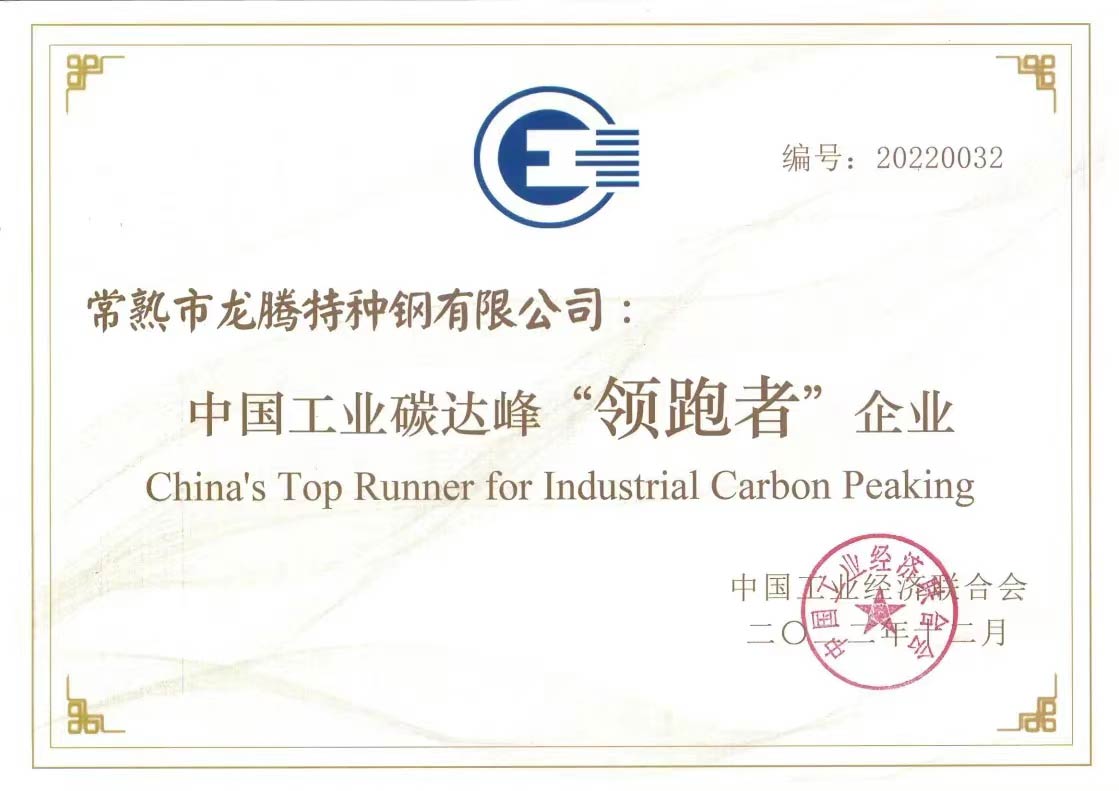

Leading Enterprises in Carbon Peaking

Leading Enterprises in Carbon Peaking

Jiangsu Province Green Factory

Jiangsu Province Green Factory

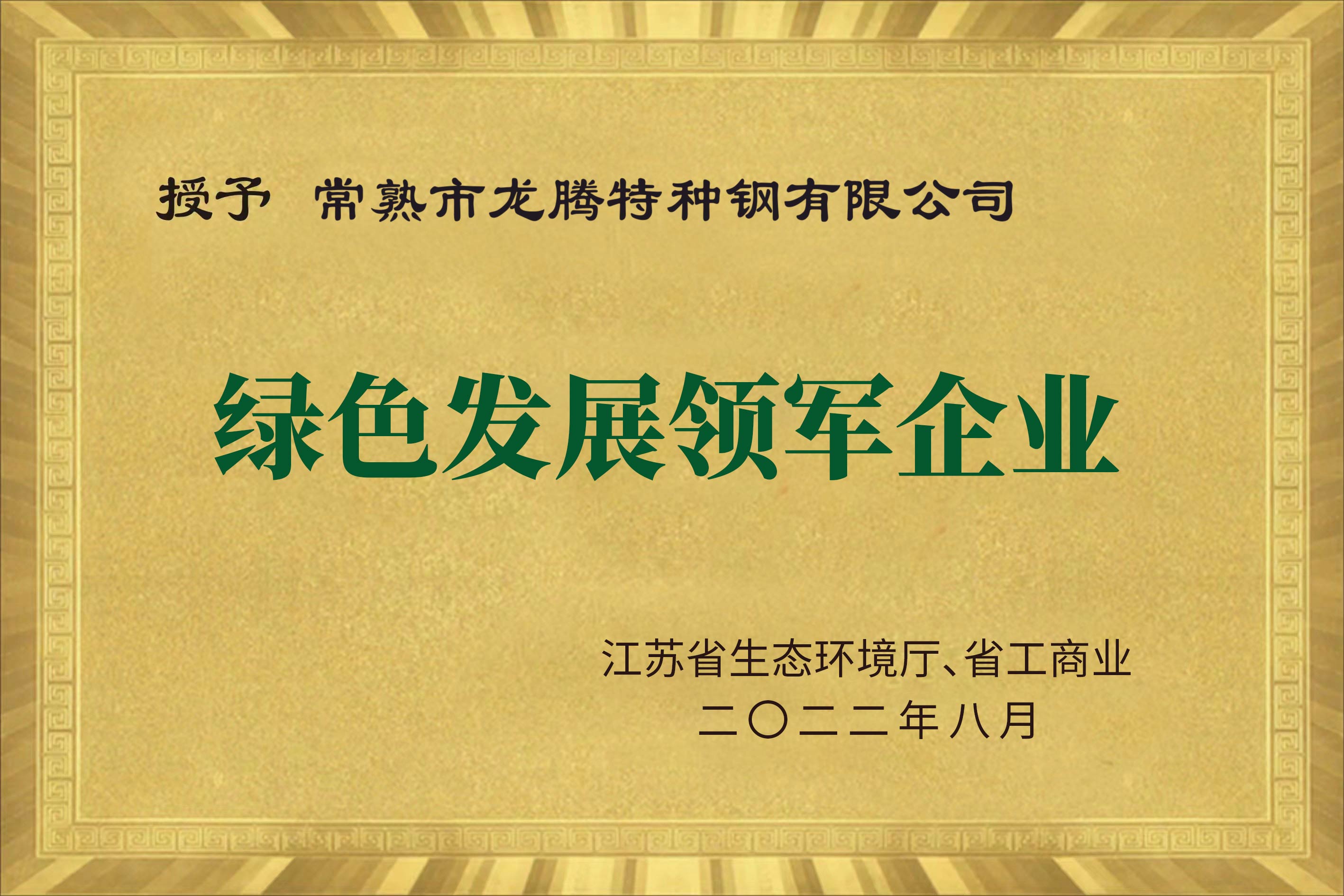

Leading enterprise in green development in Jiangsu Province

Leading enterprise in green development in Jiangsu Province

Ultra low emissions

The company hereby requests the Metallurgical Industry Planning and Research Institute to comprehensively plan and complete the ultra-low emission transformation of the entire steel process for organized and unorganized emissions and clean transportation. The "three wastes" treatment and greening and beautification projects have been fully launched, striving to win the "blue sky defense war" and achieving the goals of "using minerals without seeing minerals, transporting materials without seeing materials, environmental protection ultra-low emission, resource recycling, zero discharge of wastewater, and low energy carbonization". Industrial wastewater has reached a first-class water quality standard after deep treatment, and the "zero discharge" of recycling and reuse has been achieved, achieving harmonious coexistence between humans and nature。

- Particulate matter

2713t/a

Particulate matter2021t/a

25.50%

- Sulfur dioxide

1809t/a

Sulfur dioxide1229t/a

32.06%

- Nitrogen oxide

3100t/a

Nitrogen oxide1340t/a

56.77%

Before ultra-low emission transformation

After ultra-low emission transformation

Energy saving and carbon reduction

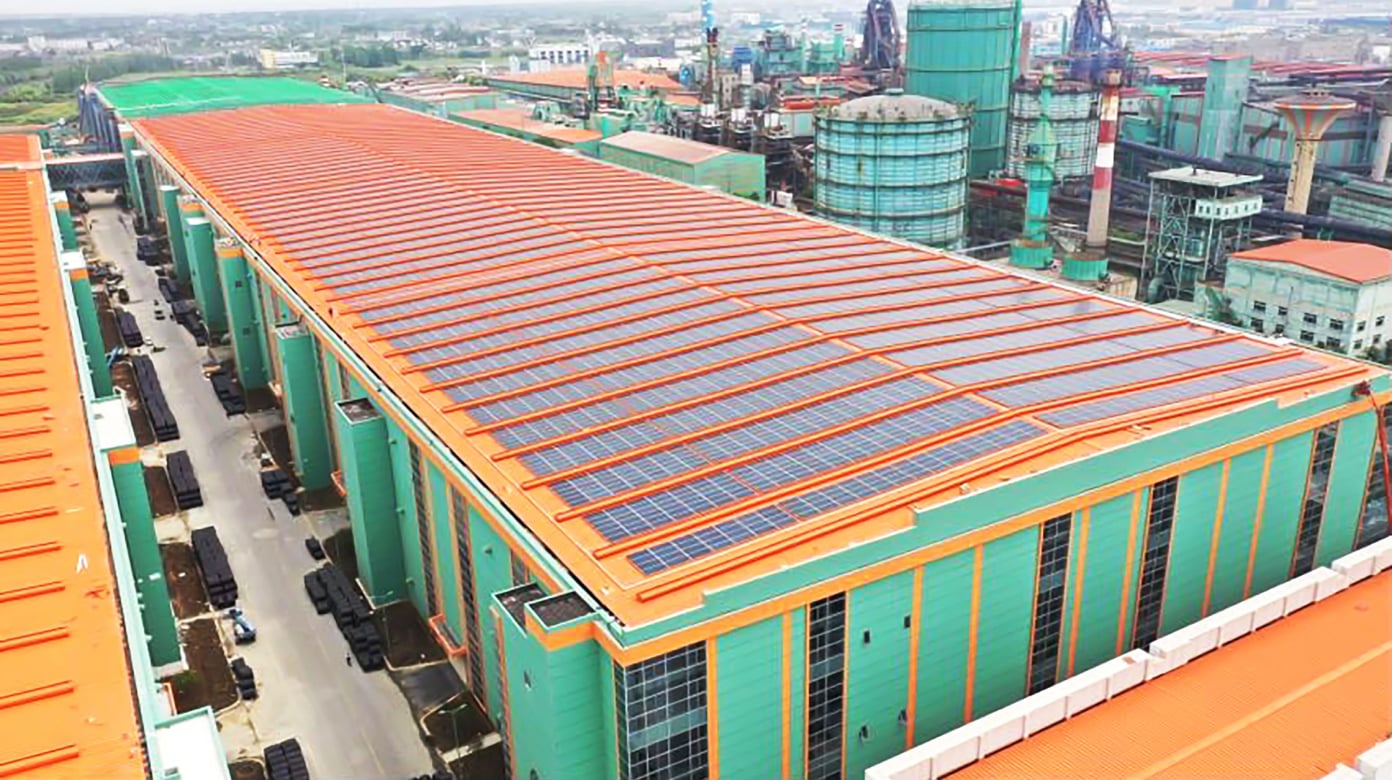

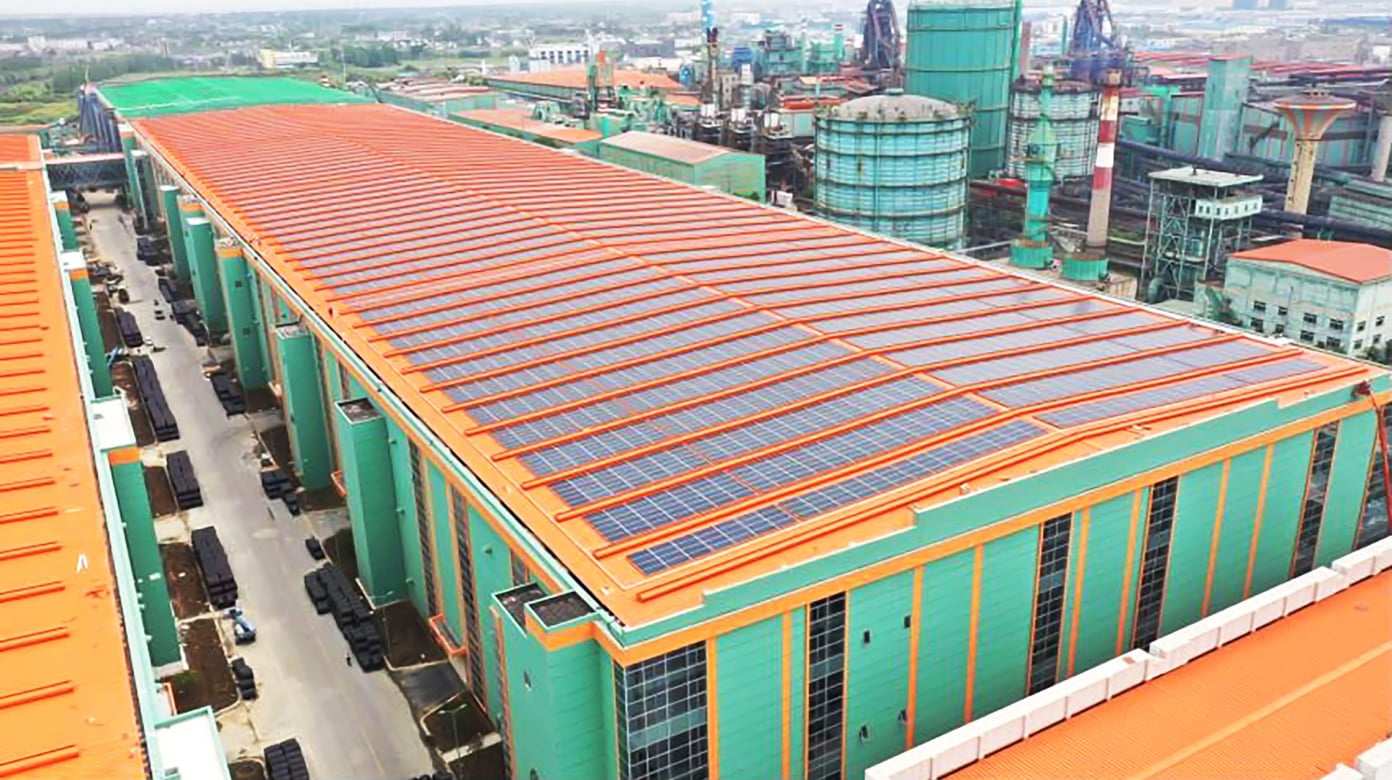

Solar energy

Low carbon technology

Longteng Special Steel has fully implemented photovoltaic power generation projects and actively utilized the contract energy management model to cooperate with Huaneng. It has completed four phases of photovoltaic power generation projects, greatly utilizing the available roof area of the company, increasing the proportion of renewable energy, achieving a synergistic effect of pollution reduction and carbon reduction for the enterprise, laying a solid foundation for achieving the "dual carbon" goals of the enterprise, and comprehensively enhancing the green competitiveness of the enterprise。

52.89Megawatt

Final assembly machine

5000Over 10000 kilowatt hours

Annual power generation

6000Remaining tons

Annual reduction of standard coal

3000Ton

Nearly annual carbon reduction

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Multiple national key energy-saving and low-carbon technologies and industry advanced technologies have been applied, including blast furnace dehumidification, ring cooler liquid sealing, thick material layer sintering technology, regenerative combustion in heating furnaces, enhanced radiation energy-saving technology in heating furnaces, variable frequency energy efficiency system for belt conveyors, and energy control in the steel industry, to improve energy efficiency and reduce greenhouse gas emissions。

Blast furnace dehumidification

Blast furnace dehumidification

Enhanced radiation energy-saving technology for heating furnaces

Enhanced radiation energy-saving technology for heating furnaces

Smart Energy Conservation

Smart Energy Conservation

Circular Economy

-

Residual gas power generation

The company has utilized its own surplus gas to construct gas power generation, and has successively built 50MW high-temperature, ultra-high pressure, and the world's first 60MW ultra-high temperature, subcritical power generation unit. While meeting the national dual carbon policy, the company has also carried out energy conservation, cost reduction, and efficiency enhancement, increasing benefits for the enterprise and ensuring production。

-

Waste heat power generation

Sintering waste heat recovery is an important way to reduce energy consumption in the sintering process and improve energy utilization efficiency. The basic principle is that the sintered ore is cooled by blowing air on the ring cooler, and the cold air blown in from the bottom is heated when passing through the hot sintered ore layer, becoming high-temperature exhaust gas. In addition, a part of the sintering machine produces sintered ore by drawing high-temperature exhaust gas from the bottom to the flue, which is introduced into the boiler through the induced draft fan, heating the water in the boiler to produce steam. The steam drives the turbine to rotate and drive the generator to generate electricity。

Ecology Factory

Fully implement ultra-low emissions and strive to build a garden factory。

Entrusted with the professional design of Nanjing Forestry University, with an investment of 150 million yuan, to build a 427 acre Longteng Ecological Picking Garden, surrounded by orchards, forests, and green shade. It integrates the "Party Building Center", "Reception Center", and "Employee Activity Center", expanding the green area of the factory to 41.3%。

1.5hundred million

Green construction investment

427Mu

Longteng Ecological Park

41.3%

Factory green area

Email

Email