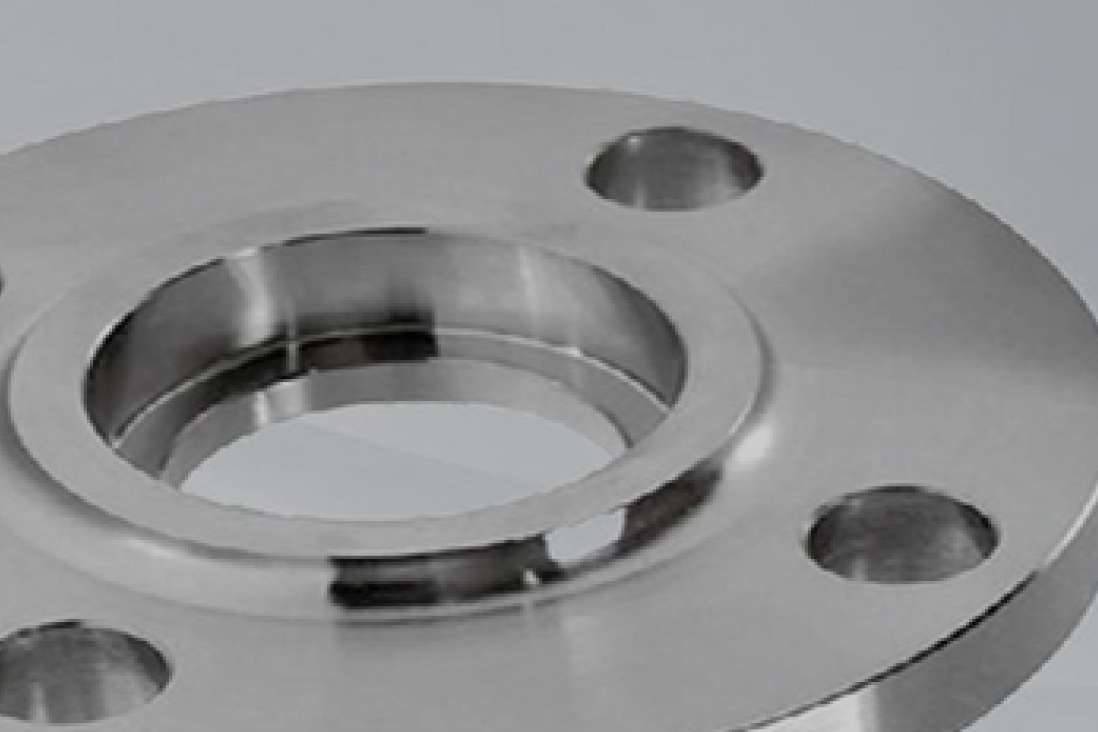

Socket Welding Flange

A socket welding flange is a flange that is welded on the pipe end and the outside by inserting the pipe end into the flange ring step. The socket welding flange has good rigidity, small welding deformation and good sealing. It is commonly used in boiler pressure vessels, petroleum, chemical industry, shipbuilding, pharmaceuticals, metallurgy, machinery, stamping elbows, food and other industries.

Specification parameters

Product specifications

Market applications

Cooperative partner

Longteng Special Steel actively seek industry cooperation, jointly promote industry progress and dev

Product certification

Advanced technology, reliable quality

Advanced technology, reliable qualityWe use the near net shape precision forging technology, the process is stable and the quality is reliable. We also use high-performance lathes to ensure the surface quality.

Complete specifications, timely delivery.

Complete specifications, timely delivery.We produce a full range of flange finished products/blanks in DN15-DN400 specifications, with strong supply guarantee capabilities, complete varieties, and 10,000 tons of inventory.

Provide excellent after-sales service methods and strategies

- Establish a comprehensive after-sales service system, cultivate a professional after-sales service team, and continuously improve the quality of after-sales service

- 7 * 24-hour timely response to customer needs

- Professional engineers provide personalized solutions

- Having professional technical means to improve after-sales service efficiency

+8613773095803

Email

Email