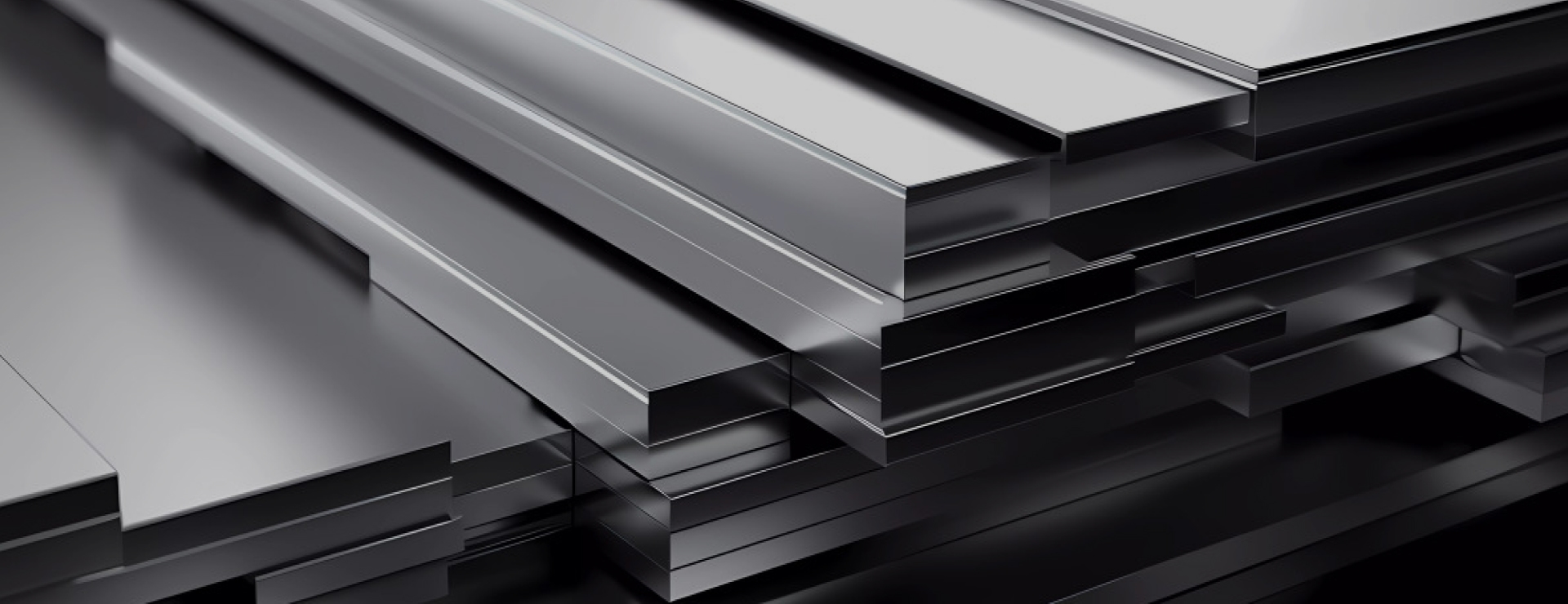

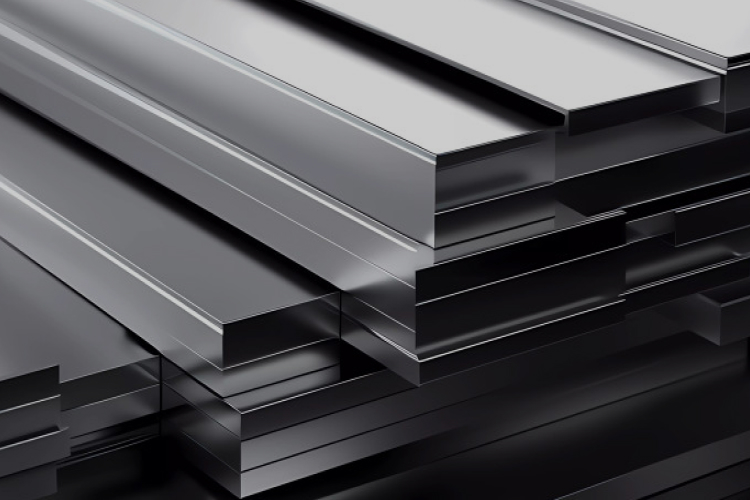

Medium Thick Steel Plate

Our plates include four series of multiple varieties and specifications, including engineering machinery steel, pipeline steel, ship and offshore steel, and pressure vessel steel, to meet customer needs. Middle thickness plate are mainly used in the shipbuilding industry, engineering machinery, offshore engineering, oil and gas pipe fittings, and construction industries. With the rapid development of the shipbuilding industry in recent years, the demand for ship steel plates is very high.

Specification parameters

Product specifications

Market applications

Cooperative partner

Longteng Special Steel actively seek industry cooperation, jointly promote industry progress and dev

Product certification

Over 70% market share

Over 70% market shareWe are the biggest manufacturing base of rolling element blanks for bearings in China, with a market share over 70% for 10 years.

Advanced technology, reliable quality

Advanced technology, reliable qualityWe use near net shape forging technology, the product has high contact fatigue life, stable process and reliable quality.

Complete specifications, timely delivery.

Complete specifications, timely delivery.We produce a full range of bearing steel ball blanks with specifications ranging from φ19.844 mm to 90 mm. We have strong supply guarantee capabilities with complete varieties, and thousands of tons of inventory.

Large equipment

Large equipmentHeavy-duty forging presses (140MN and 66MN) can meet the product process design requirements and ensure the result of the product's internal structure, surface flatness and dimensional accuracy.

Advanced production capacity

Advanced production capacityWith more than 40 industrial furnaces of various types, we are able to control product process temperature accuracy and ensure the delivery period.

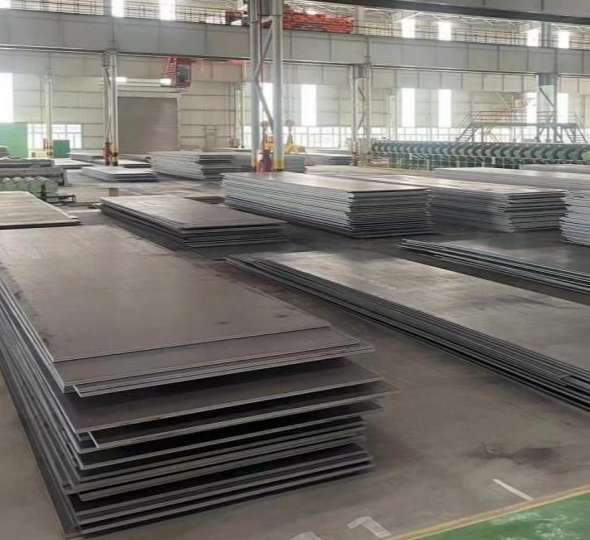

Complete variety

Complete varietyCommon thickness ranges from 6 to 400 mm, with the maximum thickness of 800 mm, meeting the full range of customer needs.

Advanced equipment

Advanced equipmentThe matching intermediate billet water-penetrating device can effectively handle rolling under differential temperature. Resulting the design of no niobium ship plate, this design can reduce alloy costs significantly.

Capacity advantage

Capacity advantageThe maximum opening of the four-roll main rolling mill is 1100mm, with the 9000 tons maximum rolling force, 1210kn.m torque, and the maximum reduction of a single pass is 60mm. The rolling capacity matches the conventional 5000 mm rolling mill, and it is equipped with a separate vertical rolling mill with the industry's largest rolling force of 800 tons. The core deformation capacity and grain refinement of the steel plate are significantly better than other manufacturers.

Technical advantages

Technical advantagesThe water volume/hour of the DQ+ACC cooling system reaches 9,000+9,000 cubic meters, which is the largest volume in the industry, and the cooling system is running with online temperature compensation technology.

Intelligent control

Intelligent controlThe entire production line is intelligently controlled and fully automatic. The ACC entrance is equipped with an advanced pre-straightening machine, and the hydraulic system adopts full servo drive.

Complete variety

Complete varietyCommon thickness ranges from 6 to 400 mm, with the maximum thickness of 800 mm, meeting the full range of customer needs.

Advanced equipment

Advanced equipmentThe matching intermediate billet water-penetrating device can effectively handle rolling under differential temperature. Resulting the design of no niobium ship plate, this design can reduce alloy costs significantly.

Provide excellent after-sales service methods and strategies

- Establish a comprehensive after-sales service system, cultivate a professional after-sales service team, and continuously improve the quality of after-sales service

- 7 * 24-hour timely response to customer needs

- Professional engineers provide personalized solutions

- Having professional technical means to improve after-sales service efficiency

+8613773095803

Email

Email