Why Construction Machinery Steel Track Shoes Are Crucial for Heavy Equipment Efficiency and Durability

2025-01-10

In the world of construction, heavy machinery is the backbone of many large-scale projects. Whether it's digging foundations, moving soil, or clearing land, these machines are designed to tackle some of the toughest and most rugged environments. One key component that ensures the optimal performance of these machines, especially tracked vehicles like bulldozers, excavators, and crawler cranes, is the construction machinery steel track shoe. These components are often taken for granted but play a pivotal role in the operational efficiency, safety, and longevity of heavy equipment. This article Longteng delves into the performance and functionality of construction machinery steel track shoes in boosting machine performance.

What Are Construction Machinery Steel Track Shoes?

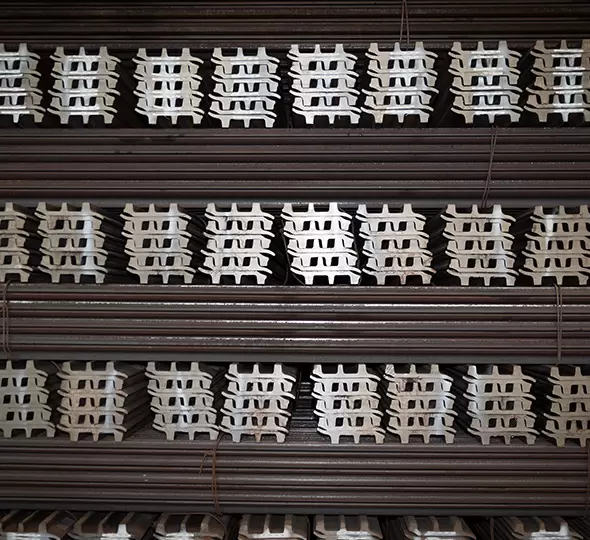

A construction machinery steel track shoe is an integral part of the track system of heavy machinery, especially those used in the construction industry. It is a heavy-duty metal plate that forms the main interface between the vehicle and the ground, providing essential support, stability, and traction. Typically welded onto the track links of a machine's undercarriage, steel track shoes enable tracked vehicles to traverse rough terrain, spread the vehicle's weight evenly, and maintain balance, regardless of the unevenness of the ground.

Construction machinery steel track shoes are not simply flat metal plates but are usually designed with special features, such as grousers or cleats, that help them grip and hold the surface of the ground. These grousers improve traction, while the strength of the steel itself ensures that the shoes can endure the constant wear and tear encountered on construction sites.

Performance and Functionality of Construction Machinery Steel Track Shoes

The construction machinery steel track shoe is one of the most critical elements of tracked equipment, as it has a direct impact on the overall performance and functionality of the machine. From providing traction and stability to protecting the undercarriage from damage, these shoes are integral to ensuring that the machine operates efficiently across various work environments.

Weight Distribution and Load-Bearing Capacity

The primary function of the construction machinery steel track shoe is to help distribute the machine's weight evenly over a large surface area. This minimizes the risk of the machine getting stuck in soft ground or sinking under its own weight. The load-bearing capacity of the track shoe is essential for heavy-duty equipment like bulldozers or excavators, which can weigh tens of tons. Track shoes help balance the weight across multiple points, reducing excessive wear on any single part of the track system. This distribution prevents damage to both the machinery and the ground, which is critical in environments where soil integrity is important.

Stability and Mobility

Construction machinery steel track shoes help ensure the stability and mobility of the machinery. For example, bulldozers and excavators often operate on steep slopes or uneven surfaces, where maintaining stability is crucial for safety. Steel track shoes help balance the vehicle and provide stability, preventing tipping or sliding during operation. In addition, the design of the track shoes, with their grousers and unique shapes, ensures that the machinery moves efficiently even in challenging environments. Whether moving over rocky terrain, wet soil, or slippery mud, the track shoes provide the necessary traction for the machine to continue its work without losing control.

Protection of the Undercarriage

The undercarriage of a tracked machine is highly susceptible to wear and tear due to its constant contact with abrasive surfaces. Steel track shoes act as a protective layer, shielding the vital components of the track system, such as rollers, sprockets, and links, from damage. Without track shoes, the undercarriage would be exposed to harsh elements, leading to faster degradation and increased maintenance costs. Construction machinery steel track shoes reduce the frequency of repairs and extend the life of the entire track system, ensuring that the machinery remains in optimal condition for longer periods, which is critical for minimizing downtime in busy construction projects

Construction machinery steel track shoes are fundamental components in ensuring the stability, mobility, and durability of tracked vehicles used in construction. By providing essential traction, weight distribution, and protection to the undercarriage, track shoes allow machinery to operate efficiently across various environments, from rocky terrains to muddy or wet conditions. With the right materials, design features, and regular maintenance, steel track shoes ensure that construction machinery performs optimally, even under the most challenging conditions. These robust, high-performance components play a crucial role in the success of construction projects, contributing significantly to the overall longevity and productivity of the machinery.

Email

Email