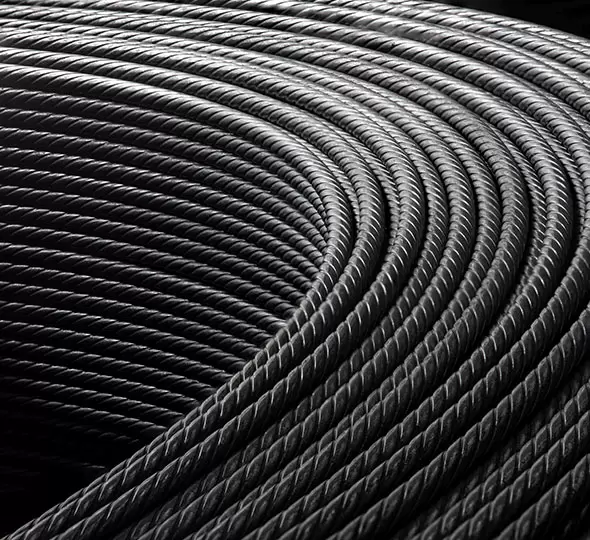

PC Bars: A Cornerstone of Modern Construction and Infrastructure

2025-01-02

The construction industry is a complex field, requiring an ever-growing range of materials, technologies, and techniques to meet the demands of modern architecture and infrastructure. Among the various structural components that play a vital role in ensuring the integrity and durability of buildings, PC bars (Prestressed Concrete Bars) have become indispensable in a variety of construction applications. In this article, Longteng will explore the applications of PC bars in the construction industry.

What Are PC Bars?

PC bars, short for Prestressed Concrete Bars, are a key element in the design and construction of prestressed concrete structures. They are made from high-strength steel wires or strands that are subjected to a process known as prestressing. During this process, the steel is stretched before being encased in concrete, ensuring that the bars remain under tension even after the concrete has set. This results in a significant increase in the load-carrying capacity and flexibility of concrete structures, allowing for more efficient and cost-effective designs.

PC bars are primarily used in the construction of large-scale infrastructure such as bridges, high-rise buildings, parking structures, and industrial facilities. They are also found in the production of precast concrete products like beams, slabs, and panels. The strength and durability of PC bars make them highly beneficial in situations where the structural elements must resist heavy loads, dynamic forces, and environmental factors like corrosion.

Applications of PC Bars in Construction

1. Bridges and Overpasses

One of the most common applications of PC bars is in the construction of bridges and overpasses. Due to the constant traffic loads and the need for structures that can withstand significant stress and strain, PC bars offer an ideal solution. The ability of PC bars to endure tension forces means that they can be used to create longer spans with thinner cross-sections, reducing the overall weight of the structure while maintaining its strength. In bridge construction, PC bars are often used in beams, girders, and deck slabs. The prestressing process ensures that these elements are not only capable of carrying the weight of the bridge but also provide resilience against the cyclical and dynamic loads typical in traffic environments. Furthermore, the durability of PC bars means that maintenance costs are minimized over the lifespan of the bridge.

2. High-Rise Buildings

High-rise buildings require materials that can provide maximum strength with minimal bulk. In this context, PC bars are often used in the structural components of skyscrapers, including beams, columns, and slabs. The prestressing process increases the tensile strength of the concrete, enabling it to handle large vertical loads while preventing cracking and deformation. The application of PC bars in high-rise construction can also reduce the amount of concrete required, making the structure more lightweight and cost-effective without compromising on performance. By incorporating PC bars into the design, architects and engineers can push the boundaries of structural design and build taller, more efficient buildings.

3. Parking Garages and Industrial Facilities

PC bars are also extensively used in the construction of parking garages and industrial facilities. These structures are subject to heavy and repetitive loads, and the use of PC bars ensures that they can withstand the demands of daily use without experiencing structural failure. The prestressed concrete elements used in these facilities offer enhanced durability against the wear and tear that results from continuous load-bearing and heavy vehicle traffic. In industrial settings, where large-scale equipment and machinery are often in operation, the use of PC bars helps provide the necessary strength to support these loads while maintaining stability. Additionally, the reduced risk of cracking in the concrete ensures that the structures remain functional for extended periods with minimal repair needs.

4. Precast Concrete Products

PC bars are a cornerstone of precast concrete manufacturing. Precast concrete refers to concrete elements that are cast in a controlled factory environment before being transported to the construction site for assembly. This process is common in the construction of modular buildings, bridges, tunnels, and other infrastructure projects. Precast concrete products such as beams, slabs, and panels benefit greatly from the use of PC bars. The prestressing of these bars ensures that the precast components have superior strength and durability, enabling them to bear greater loads and resist cracking during transportation and installation. By using PC bars in precast products, manufacturers can create elements that are both high-performing and cost-efficient.

PC bars have firmly established themselves as a vital component in modern construction. From bridges and high-rise buildings to parking garages and industrial facilities, these prestressed concrete bars provide a range of advantages that make them indispensable in ensuring structural integrity, durability, and efficiency. By offering superior load-bearing capacity, resistance to cracking, and cost savings in the long run, PC bars continue to be an essential material for creating safe, reliable, and sustainable construction projects. Whether used in precast concrete products or large-scale infrastructure projects, their role in the construction industry is indispensable, contributing to the strength and longevity of buildings and structures that shape our cities and communities.

Email

Email