Maximizing Strength and Efficiency in Shipbuilding with Bulb Flats

2024-12-13

The construction of modern ships demands structural components that combine strength, efficiency, and durability. Among these components, the bulb flat has proven to be an indispensable material in shipbuilding. Designed for optimal performance under challenging marine conditions, bulb flats offer exceptional structural support and corrosion resistance, making them ideal for various applications in ship construction. This article Longteng delves into why choose bulb flats in the shipbuilding industry, showcasing their critical contribution to maritime engineering.

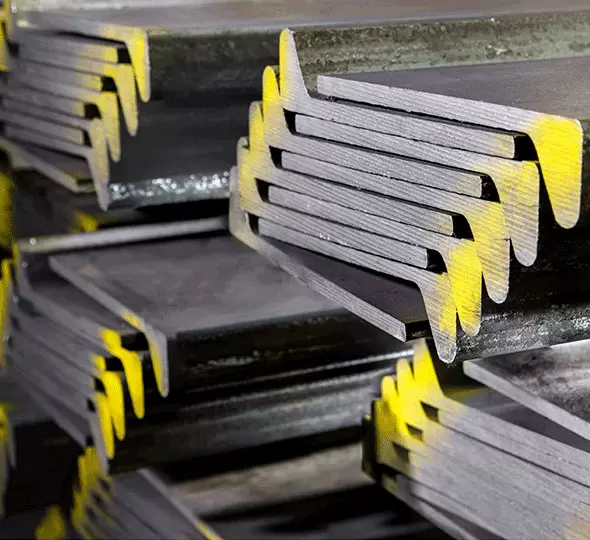

What Are Bulb Flats?

A bulb flat is a specialized steel profile used in shipbuilding, consisting of a flat surface with a rounded bulb at one end. This unique design provides a combination of strength and reduced weight, making it an essential material for shipbuilders. The bulb at the end of the flat profile enhances the load-bearing capacity of the material while maintaining structural integrity. Bulb flats are typically made of high-strength steel alloys, such as carbon steel, stainless steel, or weather-resistant steel, to meet the diverse demands of modern shipbuilding projects.The profile's geometry allows for efficient load distribution and improved structural performance. Depending on the specifications of the vessel, bulb flats are available in different sizes, thicknesses, and finishes to ensure they meet the specific strength and corrosion resistance requirements for the project.

Why Bulb Flats Are Crucial in Shipbuilding

The unique properties of bulb flats make them essential for building ships that can withstand the demanding conditions of marine operations. Here's why they are indispensable in the shipbuilding industry:

1. Lightweight Construction with High Strength

In the shipbuilding industry, minimizing weight while maintaining strength is critical. Bulb flats offer a high strength-to-weight ratio, which makes them ideal for constructing large vessels without compromising on structural stability. This is especially important when building ships like cargo vessels, tankers, and naval ships, where every reduction in weight can result in better fuel efficiency, higher speed, and reduced operational costs. By using bulb flats in the ship's structure, builders can reduce the overall displacement of the vessel, which directly contributes to improved fuel efficiency. For instance, lighter ships require less energy to propel, reducing fuel consumption and associated costs. Additionally, the reduced weight eases the construction process, allowing for faster assembly and less complicated handling of materials.

2. Excellent Load-Bearing Capabilities

Bulb flats are designed to distribute stresses and loads evenly across a ship's frame, reducing localized stress and enhancing the structural integrity of the entire vessel. This load distribution is particularly crucial in areas of the ship that experience significant forces, such as bulkheads, decks, hulls, and the keel. The load-bearing capabilities of bulb flats help ensure that these critical parts of the ship remain stable, even under extreme conditions. This design also provides stability during dynamic conditions at sea. Ships are constantly subjected to forces like wave impacts, cargo shifts, and changes in loading conditions, and bulb flats help maintain the vessel's structural integrity over time. The ability of bulb flats to absorb and distribute these forces plays a crucial role in reducing the risk of structural damage and prolonging the life of the vessel.

3. Corrosion Resistance for Marine Environments

One of the most demanding challenges in shipbuilding is dealing with the corrosive effects of saltwater, humidity, and fluctuating temperatures. Ships spend most of their operational life exposed to harsh marine environments, where traditional materials can degrade quickly if not properly protected. Bulb flats, often made from stainless steel or treated with anti-corrosion coatings, offer superior resistance to rust, pitting, and other forms of corrosion. Corrosion resistance is not just a matter of longevity; it directly impacts safety and maintenance costs. The reduced need for repairs and part replacements due to corrosion results in significant long-term savings. Additionally, fewer repairs reduce the downtime of ships, ensuring that they remain operational and efficient throughout their service life. The corrosion-resistant properties of bulb flats make them essential for critical components such as the ship's hull and other underwater structures, which are most vulnerable to environmental damage.

4. Cost-Effectiveness

While bulb flats may be more expensive than standard steel profiles, their long-term cost-effectiveness makes them a smart investment for shipbuilders. The combination of high strength, low weight, and durability results in fewer material requirements, reduced fuel costs, and lower maintenance expenditures over the lifetime of the vessel. Moreover, the ability to build lighter and stronger ships allows for more efficient designs that contribute to better overall performance. This efficiency translates into significant cost savings, especially in the shipping industry, where fuel costs and maintenance represent a large portion of operating expenses. By choosing bulb flats, shipbuilders can reduce the long-term total cost of ownership, ensuring that the vessel remains economically viable for its entire operational life.

Bulb flats have become a cornerstone of modern shipbuilding, offering a blend of strength, durability, and efficiency that is essential for creating high-performance vessels. Their unique design—combining a flat surface with a rounded bulb—ensures an optimal balance of strength and reduced weight, making them a critical material in ship construction. From reinforcing hulls and bulkheads to providing stability in deck and keel construction, bulb flats play a pivotal role in enhancing the overall structural integrity of the ship. Additionally, their corrosion resistance and cost-effectiveness ensure that ships remain operational and economically viable over their lifespan. Incorporating bulb flats into ship designs allows shipbuilders to deliver safer, more fuel-efficient, and environmentally friendly vessels that meet the evolving demands of the maritime industry. As the demand for more sustainable and high-performance ships continues to grow, bulb flats will remain an indispensable material in the shipbuilding process.

Email

Email