Bulb Flat Steel: A Key Material for Structural Excellence in Shipbuilding

2025-04-11

In the world of shipbuilding, the materials used in construction play a crucial role in determining the structural integrity, durability, and overall performance of a vessel. One such material that has gained prominence in the industry is bulb flat steel. Bulb flat steel is commonly used in shipbuilding for the construction of ship hulls and other structural components due to its superior strength, durability, and efficiency. This article Longteng explores the advantages of bulb flat steel in the shipbuilding industry.

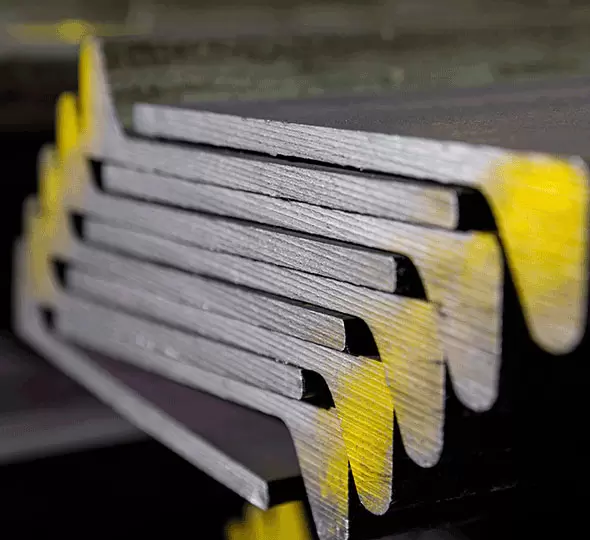

What Is Bulb Flat Steel?

Bulb flat steel is a specialized type of structural steel that has a unique cross-sectional shape resembling a flat bar with a bulbous protrusion on one side. This design allows bulb flat steel to combine the benefits of flat steel and I-beam shapes. The bulbous section offers enhanced resistance to bending, making it an ideal choice for structural applications where strength is essential. Its primary use in shipbuilding is to reinforce the hull structure, where it serves as the backbone of the vessel's construction. The bulb flat steel design is tailored to optimize strength while keeping the weight of the material to a minimum, making it essential in shipbuilding where weight efficiency is a priority.

The material is typically made from high-quality carbon steel, alloy steel, or stainless steel, depending on the required specifications. Carbon steel is frequently used for its cost-effectiveness and high tensile strength, while stainless steel may be used for additional resistance to corrosion, especially in harsh marine environments. The choice of material is typically influenced by the vessel's intended use, the environmental conditions it will face, and the expected load-bearing requirements.

Advantages of Using Bulb Flat Steel in Shipbuilding

The integration of bulb flat steel into shipbuilding offers numerous benefits that make it a preferred material for many shipbuilders around the world. These advantages include:

Durability and Longevity

Ships are constantly exposed to harsh and challenging environments, such as saltwater, extreme temperatures, and heavy weather conditions. Bulb flat steel plays a critical role in ensuring the durability and longevity of vessels. Its resistance to corrosion, particularly in marine environments, helps protect the ship's structure from deterioration over time. This durability is further enhanced by the material's strength and flexibility, which allows ships to withstand heavy loads and external pressures without compromising their integrity. As a result, ships made with bulb flat steel require less frequent repairs and maintenance, which contributes to a longer operational life. The material's resistance to wear also reduces the need for frequent replacements, making it ideal for long-term investments in shipbuilding.

Cost-Effectiveness

While bulb flat steel is known for its advanced properties and superior performance, it remains an economically viable option for shipbuilders. The design of bulb flat steel allows for the reduction of the overall weight of a vessel without compromising its strength and stability. This weight reduction has a significant impact on the vessel's fuel efficiency, leading to lower operational costs over its lifetime. Additionally, the corrosion-resistant properties of the steel mean that ships require less maintenance, thus saving money on repairs and increasing the vessel's uptime. Ship owners and operators benefit from these cost savings in the long term, especially considering the high costs of maintaining ships in good working condition. The overall affordability of bulb flat steel, combined with its longevity and performance, makes it a smart investment for shipbuilding projects.

Design Flexibility

One of the key advantages of using bulb flat steel in shipbuilding is its exceptional design flexibility. The unique shape of bulb flat steel makes it easier to incorporate into complex and customized designs. Shipbuilders can cut, weld, and shape the material according to specific requirements, allowing for precise adjustments to fit particular structural needs. Whether building a large cargo ship, a passenger vessel, or a specialized vessel such as an oil tanker or a container ship, bulb flat steel can be adapted to meet the unique challenges of each project. This adaptability is critical in ensuring that vessels meet both operational requirements and design standards. Moreover, the ease of manipulation and customization of bulb flat steel allows shipbuilders to integrate innovative features that enhance the vessel's performance and functionality.

Enhanced Stability and Safety

The structural integrity provided by bulb flat steel is essential for maintaining the stability and safety of the ship throughout its lifespan. The material's ability to distribute loads evenly across the hull enhances the vessel's structural strength, reducing the risk of failure under stress. In particular, bulb flat steel's resistance to bending and warping ensures that the ship's frame remains stable, even during challenging conditions such as rough seas or heavy cargo loading. Additionally, this material contributes to the vessel's overall balance, ensuring that the ship remains upright and stable, even when subjected to dynamic forces from waves and wind. The stability provided by bulb flat steel reduces the likelihood of accidents and structural damage, which is crucial for the safety of both the crew and the passengers onboard. With its superior ability to maintain structural integrity and stability, bulb flat steel ensures that ships can operate safely and effectively in a variety of maritime conditions.

Bulb flat steel plays an indispensable role in modern shipbuilding. Its unique design, combining strength and lightness, makes it ideal for constructing ship hulls and various other structural components. The material offers superior performance in terms of durability, load distribution, corrosion resistance, and overall structural integrity. Whether it's for enhancing the stability of the hull, supporting the deck structure, or ensuring the safety and longevity of the vessel, bulb flat steel is an essential component in shipbuilding. By understanding its advantages, shipbuilders can continue to utilize bulb flat steel to construct ships that meet the highest standards of performance and safety in the marine industry.

Email

Email