Angle Section Steel For Shipbuilding: Enhancing Structural Integrity and Performance

2025-03-07

In the world of shipbuilding, the quality and strength of materials used to construct vessels are crucial to ensuring the safety, durability, and performance of the ships. Among the many materials employed, angle section steel for shipbuilding stands out as one of the most versatile and essential components in the construction of both commercial and military vessels. Angle section steel, with its unique shape and structural properties, plays a key role in reinforcing various parts of a ship's framework, contributing to both the structural integrity and overall performance of the vessel. This article Longteng will explore the applications of angle section steel for shipbuilding, their applications, the advantages they offer in ship construction, and the reasons why this material is indispensable to the industry.

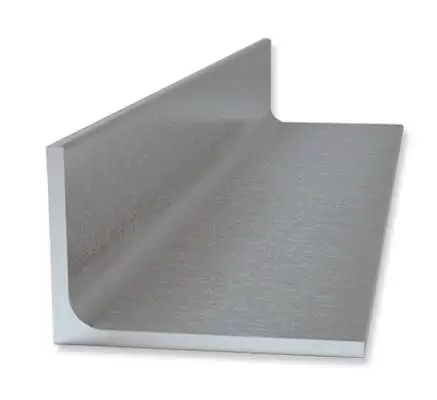

What is Angle Section Steel For Shipbuilding?

Angle section steel, commonly referred to as "angle iron," is a type of steel that is shaped like an "L" or a right-angled corner. It is widely used in construction, manufacturing, and shipbuilding because of its ability to bear heavy loads and its relative ease of fabrication. Angle section steel for shipbuilding comes in various sizes, thicknesses, and grades, allowing shipbuilders to select the most suitable option depending on the demands of the specific shipbuilding project.

The steel's angular shape makes it ideal for providing strength and support at the junctions where two structural elements meet. This feature is particularly useful in shipbuilding, where complex, multi-dimensional frameworks are required to withstand harsh marine environments.

Applications of Angle Section Steel For Shipbuilding

Angle section steel for shipbuilding serves a variety of crucial functions, all of which contribute to the vessel's overall integrity, stability, and longevity. Below are some of the key applications of angle section steel in the shipbuilding industry:

1. Hull Structure Reinforcement

The hull is the main structural body of a ship, and it must be built to withstand extreme forces, both from within the vessel (such as internal cargo) and from the outside (such as waves, winds, and sea collisions). Angle section steel for shipbuilding is used extensively in reinforcing the hull structure, particularly in the longitudinal and transverse frames, which are responsible for distributing the ship's weight and maintaining structural integrity. Angle section steel is often employed to create the ship's framework, with the angles being welded or bolted to form the skeleton of the hull. This design allows the steel to absorb and redistribute stress across the ship, ensuring the vessel can withstand the forces exerted on it during its voyages.

2. Deck and Bulkhead Support

The ship's deck and bulkheads are integral to maintaining the overall strength of the ship, and angle section steel is frequently used in their construction. Decks must support heavy loads, such as cargo, equipment, and machinery, while bulkheads provide structural divisions and enhance the ship's stability. Angle section steel for shipbuilding is used in the construction of both longitudinal and transverse bulkheads. Its ability to bear weight and distribute forces evenly makes it an ideal material for reinforcing these critical areas of the ship. Moreover, angle section steel offers resistance to bending and flexing, ensuring that the bulkheads maintain their strength under pressure.

3. Frames and Beams

In shipbuilding, the term "frames" refers to the skeleton of the ship, and the "beams" refer to the horizontal structural elements that connect the frames. Angle section steel is commonly used for both frames and beams because it provides high strength in relation to its weight. The angle section steel for shipbuilding used in frames and beams must meet specific strength and durability standards to ensure that the ship can withstand the weight of its cargo, crew, and other components. This material also plays a role in supporting the ship's propulsion system, including the engine room and other critical machinery.

4. Ship's Superstructure

The superstructure of a ship, which includes areas like the bridge, accommodations, and control rooms, requires strong materials to support the weight of the upper levels and ensure stability. Angle section steel is often used in the construction of the superstructure, especially in the areas that experience significant wind or load stresses. Angle section steel for shipbuilding is also ideal for the construction of vertical supports and braces in the ship's superstructure, where it helps maintain the overall balance and alignment of the ship.

In the shipbuilding industry, angle section steel for shipbuilding plays a crucial role in ensuring the strength, durability, and safety of ships. From hull reinforcements to superstructure supports, angle section steel provides the structural integrity needed to withstand the harsh marine environment. Its high strength-to-weight ratio, corrosion resistance, flexibility, and ease of fabrication make it an essential material in the construction of modern vessels. By choosing the appropriate type and grade of angle section steel for specific shipbuilding applications, shipbuilders can ensure that the ships they construct are not only functional but also safe and durable enough to meet the demanding conditions of the sea.

Email

Email